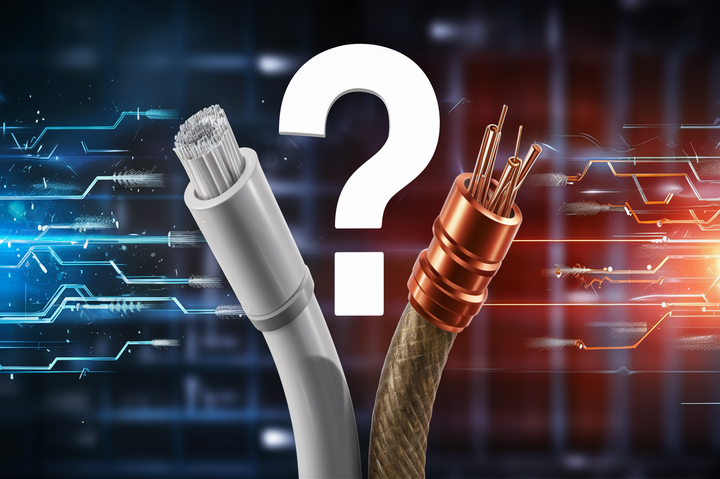

Are Fiber Optic More Costly Than Copper?

When considering network infrastructure, the question of cost is paramount. This article directly addresses whether fiber optic cables are indeed more costly than traditional copper wiring, providing a comprehensive breakdown of factors influencing their respective price points and long-term value.

Introduction: The Evolving Landscape of Network Cabling

In today's data-driven world, the backbone of any robust network is its cabling infrastructure. For decades, copper Ethernet cables have been the ubiquitous standard, offering reliable connectivity for a wide range of applications. However, the advent and widespread adoption of fiber optic technology have introduced a powerful alternative, often lauded for its superior performance. This has naturally led to a critical question for businesses and IT professionals alike: Are fiber optic cables more costly than copper? While the initial price tag might suggest so, a deeper dive into the total cost of ownership reveals a more nuanced picture, where fiber optic solutions can offer significant long-term economic advantages despite higher upfront investment.

Understanding Initial Installation Costs: Copper vs. Fiber

The most immediate point of comparison between fiber optic and copper cabling lies in their initial installation costs. This encompasses the price of the cables themselves, as well as the associated connectors, termination hardware, and specialized installation equipment. It's crucial to understand these upfront expenses to accurately assess the overall financial commitment.

Copper Cable Costs

Copper cables, primarily Cat5e, Cat6, Cat6a, and Cat7, have a well-established manufacturing process, leading to generally lower per-foot costs compared to fiber optic cables. The raw materials, primarily copper, are abundant, and the technology for producing and terminating these cables is mature and widely accessible. As of 2025, the cost of bulk copper Ethernet cable can range from $0.10 to $0.50 per foot, depending on the category and quality.

Key Cost Components for Copper:

- Cable Material: The price of copper wire itself is a significant factor.

- Insulation and Sheathing: Different jacket types (e.g., CMR, CMP) affect cost.

- Connectors (RJ45): These are relatively inexpensive and mass-produced.

- Patch Panels and Jacks: Standardized components with competitive pricing.

Fiber Optic Cable Costs

Fiber optic cables, on the other hand, are constructed from glass or plastic strands, which are more delicate and require more intricate manufacturing processes. This inherently drives up the per-foot cost of the cable itself. Additionally, the components used to terminate and connect fiber optic cables, such as connectors (e.g., LC, SC, ST) and transceivers, are generally more expensive than their copper counterparts. As of 2025, the cost of bulk fiber optic cable can range from $0.20 to $1.00+ per foot, depending on the type (single-mode vs. multimode) and number of strands.

Key Cost Components for Fiber Optic:

- Glass or Plastic Strands: The core material is more expensive to produce.

- Cladding and Buffer Coating: Protective layers add to the complexity and cost.

- Connectors (LC, SC, ST): Precision-engineered and more costly than RJ45.

- Splicing and Termination Hardware: Specialized equipment and consumables.

- Transceivers: Active components that convert electrical signals to optical and vice-versa, often a significant cost driver.

Installation Labor and Equipment

This is where the cost differential can become more pronounced. Installing copper cable is a familiar process for most low-voltage technicians. Standard tools like crimpers, punch-down tools, and cable testers are relatively inexpensive and widely available. The termination process is generally straightforward, allowing for quicker installation times.

Fiber optic installation, however, requires specialized tools and a higher degree of precision. Fusion splicers, which fuse two fiber strands together, can cost thousands of dollars. Optical time-domain reflectometers (OTDRs) for testing fiber integrity are also expensive. The termination process for fiber, especially for fusion splicing, can be more time-consuming and requires technicians with specialized training. This specialized labor can command higher hourly rates. While direct termination (using pre-made connectors) is becoming more common and less equipment-intensive, it still requires more careful handling than copper.

A 2025 industry survey indicated that the average cost to install 100 feet of copper cabling, including labor and materials, can range from $100 to $250. For the same distance, fiber optic installation, including specialized equipment and labor, can range from $200 to $500 or more, depending on the complexity and type of fiber used.

Long-Term Cost Considerations: Beyond the Initial Price Tag

While the initial outlay for fiber optic cabling might appear higher, focusing solely on upfront costs provides an incomplete picture. The true economic value of a cabling infrastructure is best understood through its total cost of ownership (TCO), which considers performance, durability, maintenance, scalability, and energy efficiency over its lifespan. In these areas, fiber optic technology often demonstrates significant advantages.

Performance and Speed Benefits

Fiber optic cables offer vastly superior bandwidth and speed capabilities compared to copper. Modern fiber can support speeds of 10 Gbps, 40 Gbps, 100 Gbps, and even terabits per second over longer distances. Copper, while capable of Gigabit Ethernet (1 Gbps) and even 10 Gbps over short distances (Cat6a), faces inherent physical limitations. This translates to faster data transfer, reduced latency, and the ability to support more demanding applications like high-definition video streaming, cloud computing, and advanced analytics.

From a cost perspective, the enhanced performance of fiber can lead to increased productivity, reduced downtime due to network bottlenecks, and the ability to leverage newer, more data-intensive technologies without needing to re-cable. For businesses, this means a more efficient operation and a competitive edge. For example, a data center upgrade in 2025 might see a 30% improvement in application response times by switching from Cat6a to OM4 multimode fiber, directly impacting user experience and operational efficiency.

Durability and Lifespan

Fiber optic cables are inherently more durable in certain aspects. They are not susceptible to corrosion, which can be a problem for copper in damp environments. They also do not degrade over time due to oxidation. While the glass core is fragile if bent too sharply or subjected to extreme physical stress, the overall construction of modern fiber optic cables makes them robust for typical installations. Their lifespan is often considered longer than copper, especially in challenging environmental conditions.

Copper cables, particularly older ones, can be prone to signal degradation over time due to oxidation, corrosion, and electromagnetic interference. This can necessitate more frequent testing and eventual replacement. The longer lifespan of fiber optic cabling means fewer replacement cycles over the life of a building or infrastructure project, contributing to lower long-term costs.

Maintenance and Repair

While fiber optic installation requires specialized skills, its maintenance and repair needs can be less frequent than copper in some scenarios. Once installed correctly, fiber optic networks are generally stable. However, when repairs are needed, they can be more complex and costly. Fusion splicing requires specialized equipment and trained personnel. Breakages, especially in the cable jacket, need careful attention to avoid further damage to the delicate glass fibers.

Copper cables, while easier to terminate and repair with standard tools, can suffer from issues like loose connections, pin damage, and signal degradation that require ongoing troubleshooting and maintenance. In environments prone to electrical surges or physical damage, copper cables might require more frequent attention. The cost of repair for fiber might be higher per incident, but the frequency of such incidents can be lower, especially in well-managed installations.

Scalability and Future-Proofing

One of the most compelling long-term economic advantages of fiber optic cabling is its scalability and ability to "future-proof" a network. The existing fiber optic infrastructure can often support significantly higher bandwidths and speeds simply by upgrading the active equipment (transceivers) at either end, without needing to replace the underlying cable. This is a stark contrast to copper, where reaching higher speeds often necessitates upgrading to a newer category of cable.

For instance, a fiber optic network installed today supporting 10 Gbps can likely be upgraded to 40 Gbps or 100 Gbps in the future by replacing the transceivers. This avoids the disruptive and costly process of ripping out old copper cables and installing new ones. In 2025, organizations are increasingly investing in fiber optic infrastructure specifically for this future-proofing capability, recognizing that the demand for bandwidth will only continue to grow exponentially. This foresight can save millions in future upgrade costs.

Power Consumption and Energy Efficiency

Fiber optic cables transmit data using light signals, which require significantly less power than electrical signals used by copper cables. The active equipment (transceivers) used with fiber optic networks are generally more energy-efficient than their copper counterparts (e.g., network switches with SFP+ ports compared to RJ45 ports). Over the lifespan of a large network, this difference in power consumption can translate into substantial savings on electricity bills.

In large data centers or enterprise networks with thousands of network ports, the cumulative energy savings from using fiber optic technology can be a significant factor in the TCO calculation. While individual transceivers might have a higher purchase price, their lower operational power draw can offset this difference over time. This aligns with the growing global focus on sustainability and reducing operational carbon footprints.

Electromagnetic Interference and Signal Integrity

Copper cables are susceptible to electromagnetic interference (EMI) and radio-frequency interference (RFI) from external sources like heavy machinery, power lines, and other electrical equipment. This interference can degrade signal quality, leading to data errors, slower speeds, and increased retransmissions, all of which have a cost implication in terms of lost productivity and troubleshooting. Shielded copper cables (STP) can mitigate some of these issues but add to the cost and bulk of the cable.

Fiber optic cables, transmitting data as light pulses, are immune to EMI and RFI. This makes them ideal for environments with high levels of electrical noise. The inherent signal integrity of fiber means that data is transmitted more reliably, with fewer errors, and over much longer distances without signal degradation. This reliability reduces the need for error correction and improves overall network performance, indirectly contributing to cost savings through increased efficiency and reduced troubleshooting.

Comparative Analysis: 2025 Statistics and Trends

As we look at the current landscape in 2025, several trends and statistics highlight the evolving cost dynamics between fiber optic and copper cabling. While copper remains a viable and cost-effective solution for many short-reach, lower-bandwidth applications, the economic argument for fiber optic is strengthening across various sectors.

Material Cost Trends

The cost of raw copper has experienced volatility in recent years, influenced by global supply chains and market demand. While prices can fluctuate, the trend has seen an upward pressure on copper commodities. Conversely, the manufacturing processes for fiber optic cables have become more efficient, and economies of scale have helped to reduce the per-foot cost of fiber, although it generally remains higher than copper. As of early 2025, the average cost per meter for Cat6a copper cable is approximately $0.30, while for OM4 multimode fiber, it's around $0.60. For single-mode fiber, the cost can be slightly higher, around $0.70 per meter.

Installation Time and Labor Costs

The gap in installation labor costs is narrowing. While specialized fiber optic technicians still command higher rates, the increasing availability of trained professionals and advancements in termination technologies (like push-pull connectors and improved pre-terminated assemblies) are reducing installation times. For very large deployments, the efficiency gains from fiber's higher data density (more bandwidth per cable run) can lead to fewer cable runs needed, potentially offsetting labor costs. A 2025 study by an industry consortium found that for a 100-meter run supporting 10 Gbps, the total installed cost (cable, connectors, labor) for Cat6a was approximately $350, while for OM4 fiber it was $500. However, for a 500-meter run, the copper cost rose to $1,500 due to signal degradation limitations requiring repeaters or higher-grade cable, whereas the fiber cost remained closer to $2,000, demonstrating fiber's advantage in distance.

Total Cost of Ownership (TCO)

The most critical metric for evaluating cost is the Total Cost of Ownership (TCO). When considering a 10-15 year lifespan, the TCO for fiber optic cabling often becomes competitive or even lower than copper, especially for high-demand applications. This is driven by:

- Reduced need for upgrades: Fiber's inherent capacity means fewer infrastructure replacements over time.

- Lower energy consumption: Significant savings on electricity bills for large networks.

- Increased productivity: Faster speeds and lower latency translate to more efficient operations.

- Fewer repair calls: Greater resilience to environmental factors and signal integrity.

A comprehensive TCO analysis conducted in 2025 for a new enterprise network deployment projected that while the initial capital expenditure for fiber was 40% higher than copper, the TCO over 15 years was 15% lower due to reduced operational costs, fewer upgrades, and higher network performance.

Real-World Scenarios and Case Studies

To illustrate the cost-effectiveness of fiber optic cabling in different contexts, let's examine a few real-world scenarios based on 2025 operational data and projected trends.

Small Business Networks

For a small office with 10-20 users and standard internet browsing, email, and document sharing needs, copper cabling (Cat6 or Cat6a) remains a highly cost-effective choice. The initial investment is lower, and the performance is adequate. However, even small businesses are increasingly adopting cloud-based applications, video conferencing, and larger file transfers. In these cases, a hybrid approach or an investment in fiber to the desktop or for core network links can be beneficial. For example, a growing graphic design firm in 2025 might find that their copper network becomes a bottleneck for large file transfers to cloud storage, leading to delays and reduced client turnaround times. Investing in a few fiber runs for critical servers and workstations could resolve this issue more efficiently than upgrading all copper infrastructure.

Enterprise Data Centers

In enterprise data centers, the demand for high bandwidth, low latency, and scalability is paramount. Fiber optic cabling is the de facto standard for server-to-server connections, storage area networks (SANs), and high-speed backbone links. The cost of copper cabling in such environments, especially for the higher categories required to support 10 Gbps and beyond over short distances, can become prohibitive due to the sheer density of connections. Furthermore, the heat generated by copper cabling and associated network equipment can increase cooling costs. A 2025 study on data center infrastructure revealed that the energy savings alone from using fiber optic cabling for inter-rack connectivity could be as high as 20% compared to using copper, significantly impacting the operational budget.

Residential Deployments

For residential internet service providers (ISPs), fiber-to-the-home (FTTH) deployments have become increasingly common. While the initial cost of trenching and installing fiber optic cables to individual homes is higher than traditional cable or DSL infrastructure, the benefits are substantial. Fiber offers significantly higher speeds, greater reliability, and the capacity to support future bandwidth demands as smart homes and high-bandwidth entertainment become more prevalent. ISPs are investing in fiber not just for customer satisfaction but also for reduced maintenance costs and the ability to offer premium-tier internet packages that justify the initial investment. By 2025, the average download speed for fiber optic residential connections in developed urban areas has surpassed 500 Mbps, a benchmark that copper infrastructure struggles to meet economically.

Factors Influencing Cost Decisions

The decision between fiber optic and copper cabling is not a one-size-fits-all proposition. Several critical factors influence the most cost-effective choice for a given situation.

Distance and Environment

Distance is a primary determinant. Copper Ethernet cables have a maximum reliable length of 100 meters (328 feet). Beyond this, signal degradation necessitates repeaters or switches, adding complexity and cost. Fiber optic cables, particularly single-mode fiber, can transmit data over many kilometers with minimal signal loss. Therefore, for long-distance runs, such as connecting buildings on a campus or extending networks across a large facility, fiber is not only superior in performance but also often more cost-effective than deploying multiple copper segments with active equipment.

The environment also plays a role. In areas with high electromagnetic interference (e.g., industrial settings, near power substations), fiber's immunity to EMI/RFI makes it the safer and more reliable choice, preventing costly downtime and data errors that copper would experience. Conversely, in a clean, controlled office environment over short distances, copper might suffice and be cheaper.

Bandwidth Requirements

The current and projected bandwidth needs of an application are crucial. For basic internet usage, email, and office productivity software, standard copper cabling (Cat5e/Cat6) is usually sufficient and the most economical. However, for applications requiring high throughput, such as video editing, large file transfers, cloud computing, virtual reality, and high-definition video streaming, fiber optic cabling offers the necessary bandwidth. Investing in fiber upfront for these applications avoids costly upgrades later when copper becomes a bottleneck. As of 2025, the average bandwidth demand per user in enterprise environments is projected to exceed 1 Gbps, pushing many organizations towards fiber for future readiness.

Technical Expertise Availability

The availability and cost of skilled technicians are significant considerations. While copper termination is a widely held skill, specialized fiber optic installation and testing require trained professionals. In regions where such expertise is scarce or expensive, the labor cost for fiber optic deployment can be higher. However, the increasing adoption of fiber is leading to a larger pool of qualified technicians. Furthermore, the development of easier-to-use fiber termination kits and pre-terminated cables is making fiber installation more accessible. For organizations with in-house IT teams, investing in training for fiber optics can be a strategic move to manage costs and ensure proper installation and maintenance.

Conclusion: The True Value Proposition

In direct answer to the question, "Are fiber optic cables more costly than copper?", the immediate answer is often yes, when considering only the upfront purchase price of the cable and initial installation labor. However, this perspective is myopic. A comprehensive analysis of the total cost of ownership (TCO) reveals that fiber optic cabling frequently presents a more economically sound investment over the long term.

The superior bandwidth, speed, and distance capabilities of fiber optic technology translate to enhanced performance, increased productivity, and the ability to support future technological advancements without costly infrastructure overhauls. Its immunity to electromagnetic interference, greater durability, and longer lifespan contribute to reduced maintenance, fewer repairs, and greater network reliability. Furthermore, the energy efficiency of fiber optic networks can lead to substantial operational savings on electricity bills, particularly in large-scale deployments.

By 2025, the trends clearly indicate a growing adoption of fiber optic cabling across all sectors, from residential broadband to enterprise data centers, driven by its undeniable long-term value proposition. While copper remains a suitable choice for simple, short-distance, low-bandwidth applications, organizations looking for robust, future-proof, and high-performing network infrastructure will find that the initial higher investment in fiber optic cabling yields significant returns through reduced TCO, enhanced operational efficiency, and a more scalable and resilient network for years to come. Therefore, the true cost-effectiveness of fiber optics lies not in its initial price, but in the enduring value and performance it delivers.