How does fiber internet get installed?

Fiber AT&T Internet is also increasing in popularity as more providers lay down their fiber optic lines. Fiber internet is very fast, reliable, and can handle multiple devices as well as data-hungry applications. However, one may ask what process does a home or business go through to be connected to fiber? Below is a brief description of how fiber is installed.

Planning and Design

One of the initial processes through which fiber internet is introduced in a new location is the planning of the network and fiber lines. Internet providers determine where they want to locate the hubs, aggregation points, distribution lines, and individual fibers for connection to homes and businesses. They assess factors like:

- Areas where there is no availability of broadband connection or areas that require high speed.

- Regulations that govern zoning and permitting the running of new utilities

- The existing ground conditions and the presence of underground services such as sewerage and water pipes

- Fiber optic cable connection path that would be most appropriate for the hubs and endpoints

With these details in place, they are in a position to determine how the physical fiber network would look like, source materials for the same and get construction plans sanctioned for implementation before deployment.

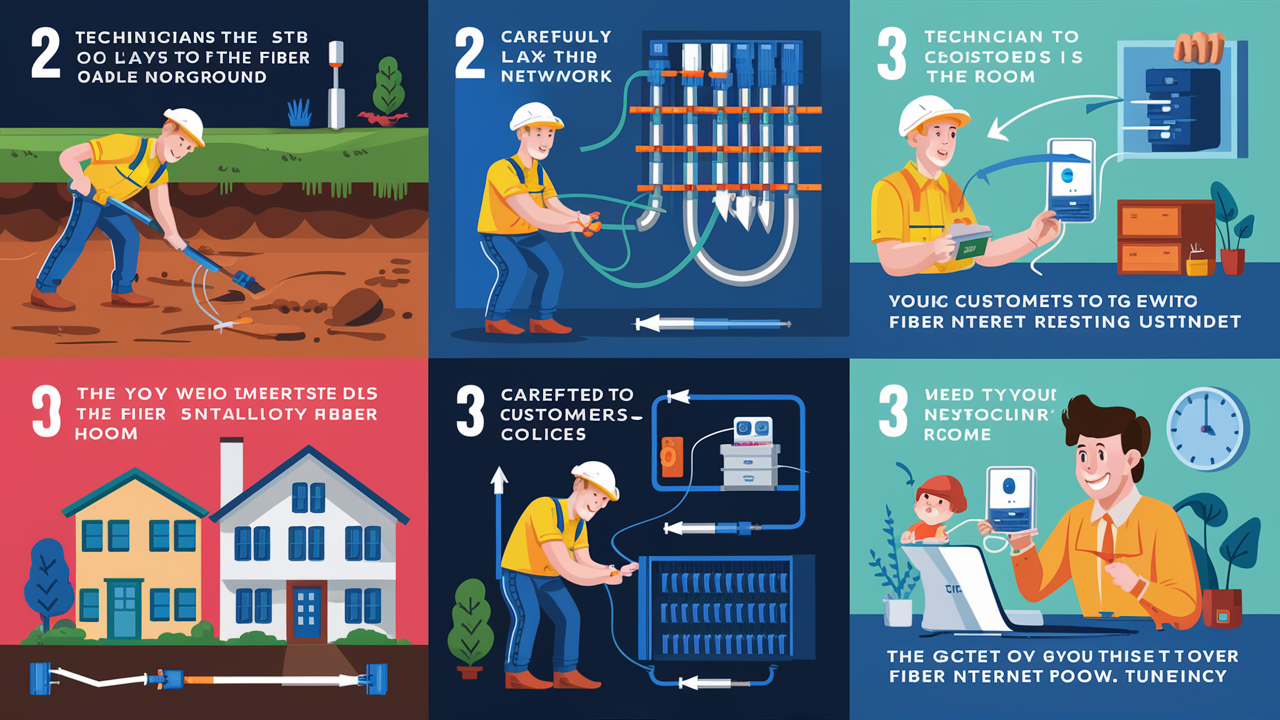

Backbone Fiber Installation

The internet provider begins by deploying large long-distance fiber optic cables that act as the ‘backbone’ for relaying data in the form of light across a complete geographical area. Several concealed conduits may each accommodate many strands of fibers.

This backbone infrastructure links the main data routing facilities together and then provides the connection into neighborhoods based on that foundation. The fiber backbone lies buried but can be strung on telephone poles in specific areas.

Special equipment carves out a narrow trench or bores a pathway underground as crews lay down the heavy-duty fiber cables. It might be located adjacent to roads, highways, rail lines, or other accessible linear rights-of-way to route the regional information highway backbone through the provider’s infrastructure.

Local Distribution Fiber

Once the larger network backbone structure is in place, providers use local distribution fiber lines to the homes and businesses. Design and installation are similar, but are at a more detailed level within a particular geography and building environments in that context.

Distribution conduits or cables are laid along utility poles and junction boxes or encased in the ground often paralleling electric and telephone wires. This takes signals and disseminates them to a proximity for the final fiber drop connections.

Fiber Drop Installations

The fiber drop wire is used to link the buildings from the nearest distribution access point from the street or alleyway utility poles and junctions. They deploy installers to feed a slim fiber optic cable directly into the premises from the distribution fiber cable nearby.

For buried drop cable routes, they make narrow trenches up to a property for conduits or lay the micro duct cable. Technicians also can run thin fiber lines aerially along the utility poles from a pole-mounted junction box to the outer walls of houses and business premises. The customers can decide on the best route that suits their fiber drop access point best.

The drop cables also come to an end at an Optical Network Terminal located indoors or outdoors within the building. This device is responsible for accepting the fiber line and translating the light data signals to electrical signals for internal usage.

Wiring and Fiber Modem Installation

Once the initial outside lines establish the fiber optic path, an inside plant professional strings category 5 or 6 data wiring within a home or business to the desired router zones and rooms. These link this wiring back to the Optical Network Terminal. This inside wiring provides the Wi-Fi router(s) with the fiber signals.

Last of all, the provider installs the specialized Fiber Internet modem and router, checks the speeds, and provides the connection. This piece of equipment transforms the light wavelengths passing over the glass fiber into the normal internet data that the computer can comprehend and is either transmitted wirelessly or through inside wired Ethernet cables – all delivered with lightning-fast fiber speed across the building!

A separate fiber line through the Types of Fiber Optic Cables Used

Another fundamental benefit of fiber internet is having a private route exclusively for that location’s use instead of bandwidth dynamically used by multiple homes. This translates to synonymous speeds that are free from interruptions by the neighborhood network.

While the long haul backbone cables utilize heavy-duty reinforced constructs with dozens or hundreds of fiber strands, the distribution and drop cables are more lightweight designs.

- Underground distribution lines are typically composed of tough polyethylene duct-style fiber bundles ranging from 6 to 144 fibers

- Aerial lines use a suspended fiber optic cable with metal-strength members for reinforcement.

- The feeder and drop cables use the flexible ‘soft-sheath’ micro-cables with 1 to 12 strands for each home or business.

More broadly, there is a need for considerable expertise, strategic planning, physical construction, and within-building cabling proficiency to build a broad fiber optic network. However, investment in such a state-of-the-art internet pipeline delivers fruits in terms of dramatically improved connectivity speed, capability, and the prospective carrying capacity ready to support escalating the need in future generations.

Upgrade to faster, more reliable AT&T Fiber Internet today! Call us at +1 844-905-5002 and get connected with speeds that keep you ahead.